Can 3D Printing Stitch A “Design in India” To “Make In India” Story?

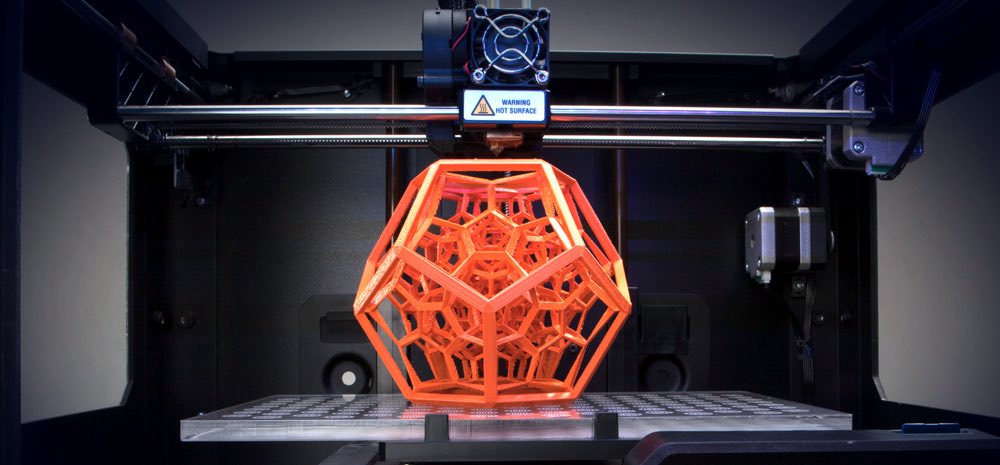

3D Printing can be the next big thing in the Make In India story.

In 2009, the Indian government unveiled a Task Force report to stimulate the growth of IT, ITES and Electronics Manufacturing industry in India. What followed is the launch of “Make in India” campaign in 2014.

While the buzz revolves around assembling, there was very little movement happened towards building competitive advantage on a global scale. Additive technology, more popular as 3D printing, may hold the key to success to Make in India.

3D Printing: A “Make In India” Story?

Research firm IDC stated that 3D Printing or Additive Manufacturing can be the next big thing in manufacturing technology. The IDC estimate suggests 20% of manufacturers from India will begin to evaluate Robotics/3D-Printer Hybrids for the production floor by 2021.

Many are not aware that in 2009, Imaginarium, a Mumbai-based 3D printing solutions company also started their journey to stimulate indigenous manufacturing. By the time, Make in India campaign was launched, Imaginarium already made inroads into automotive, aerospace, FMCG packaging, home appliances, medical devices and every industry that requires manufacturing.

IDC also echoed the strong potential 3D printing holds in the manufacturing space.

“Automotive sector is one of the first sectors to adopt 3D printing for prototyping. However, technology has huge scope in aerospace, architecture, defense, jewellery and medical. Still, automotive sector is expected to be leader in additive manufacturing because of its large volume and size,” says Pankaj Chawla, Research Manager, Imaging, Printing & Document Solutions (IPDS), IDC

While today usage of additive manufacturing is limited to prototyping, various printing service companies are entering in this space. Manufacturers can outsource their additive manufacturing needs to these print service providers. By 2021, IDC expects 25% of manufacturers to adopt a 3D-Printing collaborative platform within their supply chain in order to better leverage the broader ecosystem of 3D Printing Services.

Even, a 6Wresearch prediction has indicated that India’s 3D printer prototyping and materials market will hit $79 million by 2021.

Gradual Rate Of Adoption

“The higher majority of our work is in the prototyping segment where we make the first pieces and sometimes, we make end-used,” says Atit Kothari, Business Development – Leadership Team at Imaginarium.

In India, adoption of additive manufacturing is slow as compared to western economies. Today manufacturing organizations and users of 3D printers are evaluating new materials to develop parts, which could replace existing parts and for customization.

Not only Imaginarium, there are players like ALTEM Technologies, Brahma 3, think3D and many others who are working towards stitching the 3D printing story with Make in India.

Global OEMs have also identified the opportunity and introduced many high-end printers. Recently HP launched 3D printers for India, priced at Rs.2.5 crores.

With our Prime Minister, Narendra Modi dreaming of making India as a global manufacturing hub, will 3D printing ignite the idea of value creation through “Design in India”.

Do you think 3D printing can create a new ‘Make in India’ story and stimulate the next industrial revolution in India?