How Indian textile manufacturers can become European retailers [Reverse Outsourcing]

The business of Indian textile industry largely relies on catering to the needs of foreign customers. That’s by all means a good business model that works well for most of the companies. It allows of running a focused and specialized operation, limits risks related to issues related to retailing, logistics and etc. But overall, outsourcing model is way more beneficial to fashion brands, not to the manufacturers. F

or anecdotal evidence of that, you may check how many persons on Forbes Billionaires top 10 list, are from the fashion retail business and how many from the textile manufacturing business (hint: 3 and 0).

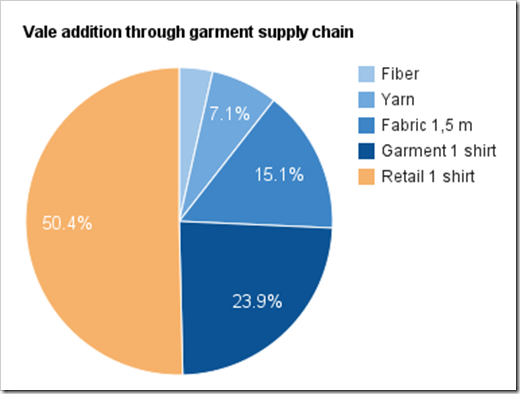

During the last few decades garment manufacturing has become to great extent a commoditized service. In most cases fashion brands can easily shift from supplier to supplier without customer ever noticing the change. It’s one of the main reasons why profit distribution within the supply chain is skewed towards the retailer’s side (Figure given below illustrates value distribution with the supply chain for a shirt). It doesn’t seem likely that this major trend will change any time soon.

Reverse-outsourcing business model is enabling manufacturers from a low cost country of becoming retailers in a higher income one. The concept is essentially the same as in outsourcing of manufacturing to a lower cost location, but in reverse – in this case services of the retailing, distribution and marketing are being outsourced to the end market.

Manufacturer has various benefits to be gained from going into such a business. First, this way the demand for what’s produced is created. And that is beneficial for limiting the risks related to seasonal fluctuations or loss of client. Second, it allows capturing profits within a more lucrative segment of a supply chain – i.e. retailing [Figure 1]. Third, geographical diversification might be beneficial balancing effects of economic cycles.

Most, even medium sized, Indian manufacturers are well placed to run such an operation – usually management has decades of business experience, deep knowledge of garmenting business, and follows global trends often better than many fashion brands. The fact that garment manufacturing in India is predominantly family-owned business, is also advantageous in this case – it allows taking fast and bold decisions.

Within this framework, Eastern Europe is a market where Indian manufacturers have high potential of being successful with their own fashion labels. The market is rapidly growing and is not yet saturated (due to this fact, average price level is often higher than it is in highly competitive Western Europe). Second, competition from other Indian businessman (who potentially, have access to the same skills, technologies and labor) is very low.

Starting retailing business in your own country might seem as an easier undertaking, but exactly for the same reason growing abroad is might be more rewarding financially. It’s about having competitive advantages. There are tens of thousands of textile related enterprises in NCR alone, and many have similar access to recourses and skills. While in a country such as Lithuania, an Indian businessman is a rare find.

In no way, I would claim that it is easy to build a leading fashion brand, or a big business in Easter Europe (or to that matter, anywhere else). The point I’m trying to make is that Eastern Europe is currently underserved, less explored, rapidly developing market, which is largely undiscovered by Indian businesses. These peculiarities enable professional Indian manufacturers (and there are so many of them) to realistically aim of building a healthy, few million-euro in turnover, business.

The world is changing all the time, and there is no doubt that we will see many more supply chain innovations initiated by the manufacturers. I’m experiencing changes myself as some of the forward-thinking Indian entrepreneurs have chosen to take the path of “reverse-outsourcing” with us in Lithuania.

[Author: Mantas Balcius is an entrepreneur and business development consultant in Lithuania, Turkey and India. He’s a creator of www.indialithuniabusiness.com. Twitter @mantasbalcius]

[Author: Mantas Balcius is an entrepreneur and business development consultant in Lithuania, Turkey and India. He’s a creator of www.indialithuniabusiness.com. Twitter @mantasbalcius]

India is the world’s second largest producer of textiles and garments after China.

It is the world’s third largest producer of cotton after China and the USA and the

second largest cotton consumer after China. This reverse outsourcing concept sounds great as because of this India has contributed $105 billion to the US economy and in created jobs also.

Wake up Orientcraft!

Hey Nimesh… Orientcraft?