Find Out Why Electronics, Auto Firms Can Reduce Output From April

Production of consumer electronics and automobiles in India will probably be reduced from April, the reason being a shortage of components from China and Hong Kong.

Another lockdown has been imposed in China, due to the rapidly increasing cases of COVID-19 patients.

Electronic and Automobile Companies To Cut Production From April

As per company executives, consumer electronic companies will also have no other option left than to reduce production from next month.

Apparently, the companies importing finished goods from China may also face inventory shortages too. Laptops, large refrigerators, large screen televisions, dishwashers, audio products, microwave ovens are some of the finished products that are imported from China.

“Shipments are already delayed by 10-15 days, which will impact production next month,” said Pradeep Jain, managing director of Jaina Group, which retails Karbonn and Sansui brands.

As per reports, there is a 40-50% dependency on China for raw materials from Indian electronic companies. This is quite lesser than 70-75% share of Chinese components, prior to pandemic caused by the Chinese virus.

Several cities in China are under a strict lockdown due to a record number of cases detected in the country, and this includes Shenzhen, the technology capital of China as well. Also, border movement at Hong Kong has also been restricted.

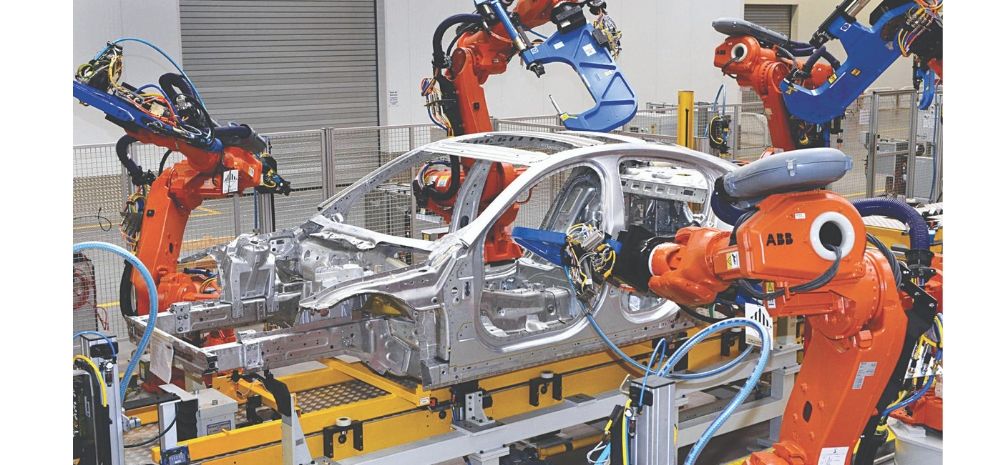

China Is Key Sourcing Base For Automobile Manufacturing Companies

Also, automobile manufacturers are also dealing with shortage issues, as China is one of the largest component sourcing markets.

Even for automobiles, China is a key sourcing base for many commodities and components for the Indian automobile industry.

As per Vinnie Mehta, director general, Automotive Component Manufacturers Association, “The auto sector is already facing a lot of headwinds – from the spike in commodity prices to supply chain disruption because of the geopolitical crisis to the semiconductor shortage. This will add another element of uncertainty and cost.”

The passenger vehicle industry has suffered from a huge loss already. In 2021-2022, there has been a loss of revenue of Rs. 40,000 crores. The industry is reportedly waiting on a vehicle order book of more than 500,000 units for around six months.

Both the electronic and automobile markets were hoping to amp up the production, now that the issue of semiconductor shortage is no longer a huge issue. The domestic demand is also high, and the cases of COVID-19 patients are dwindling in India.

Comments are closed, but trackbacks and pingbacks are open.