The Importance of Product Packaging in This New Age of ECommerce

We all purchase a lot of goods which come in a variety of packaging. Especially with the advent of e-commerce, we now find that packaging and packing has gained a lot of attention these days. This write-up of mine intends to take you through some aspects of packaging which are relevant to you directly as well as some other fascinating aspects which may make for some interesting reading.

Contents

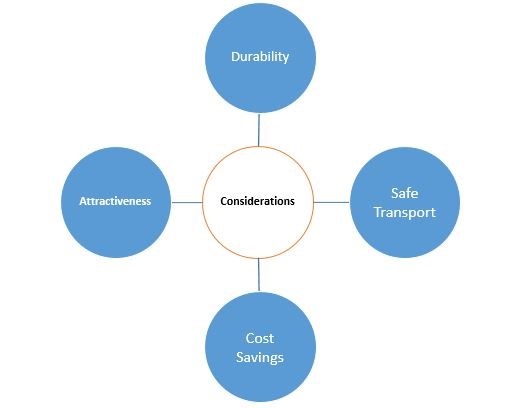

Considerations while Designing a Package!

It is sometimes remarked that designing a package for a product is as important as designing that product itself. While automation in packaging has certainly helped matters to an extent, it obviously cannot replace the various permutations and combinations that packagers have to go through before finalising a package for a particular product. It includes trial runs and calculating the wastage while optimising the length of master sheets required.

Packaging by itself performs many functions. Retail packaging is especially designed to attract end use consumers. It includes the colour scheme, strength of box (we will discuss that in some detail later on) and fitting of product. Well, if you purchased a new product but even before you go home, the package inadvertently opened up because of improper packing, imagine the fall in brand value in your eyes for the product as well.

Wholesale or industrial or in-transit packaging (like outer cartons) is used primarily to ensure two things- safety of the product and no change in the character of the product.

Let us have a look at the below picture:

Let us look at them one by one:

1. Durability:

This is the most basic and vital function of any packaging. Packaging is primarily meant to ensure that the product remains as-it-is without any interference from outside elements. The strongest packaging is used for the most fragile products like ceramics, antiques, thin plastic products etc. Many a times multiple packing is carried out to act as buffers. In cases of liquid products, packaging methods like air tight packaging is carried out to avoid spills.

Material used in packaging is very important in case of edible or chemical or pharma products where the packaging shall neither cause any change in the character or composition of the product nor allow outside elements to do the same. Plastic or glass, being inert substances, is preferred for the same. Likewise, we have cases of air-tight packaging where even air is not allowed to interact with a packaging to maintain its freshness, flavour and to increase its shelf life.

2. Safe Transport:

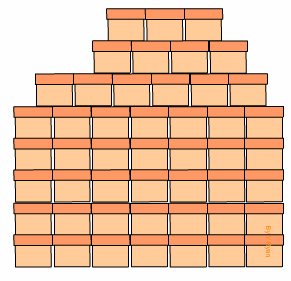

This is again very important requirement expected from packaging function. It caters mainly to outer cartons and second or third layer of packaging. You may appreciate a very fact which is very important but not visible to end users – Stacking of Goods one over another. Usually in transportation by ship containers, the goods are stacked one over another.

something like this: —

If you notice the packet at the end bears the weight of all the goods stacked over it. The package has to be strong enough to bear that otherwise we often see cases of packs being doggy-eared and split at the corners. Decision whether a package has to be 3 ply or 5 ply or 7 ply plays a major role.

Again, for carrying heavy packages, sometimes we see small tweaks or handles or indents at the sides of packets. These are mainly simple changes but require a lot of foresight at the time of designing a package.

While considering safe transport, an important factor is the distance involved as also the time taken to travel. It is obvious that the strength of packaging is a direct function of the distance and time involved during the transportation of goods. Greater the distance and time required, stronger the packaging should be to protect the product from all external factors like humidity, wear and tear while handling etc.

Further, if goods are to be transported via cold freezers or stored in cold warehouses, then separate packaging material shall be required which can withstand the extreme cold.

3. Attractiveness:

Mainly in focus at the time of retail packages. This is used to attract the attention of end user consumers. Sometimes an excellently designed package helps the product to stand out in a showroom or a super market and hence becomes the driving force behind the sale of that product. It is very helpful especially in case of new products which don’t have an existing brand recall value. The material used, colour combination etc. are very important in such cases.

4. Cost savings:

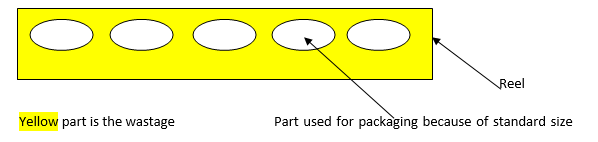

This is something which is very important for the manufacturer or the trader who is re-packing the goods. The important factors in cost are – material used, labour used, layers of packing, printing costs and the wastage incurred. While the others are fairly obvious, let me explain the last one i.e. wastage incurred. Any packaging material comes in sheets or rolls manufactured from the factory. These are usually standard sizes while size of each new product which is manufactured may be different from other type of products.

Wastages, if not eliminated to the maximum, while designing the package, adds to the “per unit” cost and leads to reduction in profits and also impacts the competitiveness of the product.

But if there is proper planning and reel size is ordered accordingly, wastage can be minimized like the following:

Again, cost savings depend on the target consumer market. This is really a simple equation because for a high spending consumer base, the price charged will more than adequately cover a more expensive package but for a mass base item, focus is on cost savings and hence a very expensive packaging is out of the question.

Dimensions of the product i.e. its length, breadth, width and height are to be considered in the most detailed manner so that the package is neither too small nor large but is of a optimum size so as to arrive at the optimum costs.

Research to Find The Right Package for a Product:

A lot of thought, design goes into finalising the package for a particular product be it an AC or mobile or jewellery or industrial machinery.While packaging has various dimensions like paper packaging, plastic packaging, glass packaging, metal packaging, it would be in order for me to focus on corrugated paper packaging which comes the most in my domain and for which I can say with authority a lot more than other types of packaging. I will explain briefly the various terminologies of box packaging. These are technical details as such but I will try to simplify them as much as I can:

1. Corrugated Board: It means ‘fluted paper’ (for fluted, see below), when stuck to another flat sheet of paper.

2. Fluted paper: It means the generic configurations formed by wavelike shapes of the corrugated medium in corrugated photo

3. Ply – WE have 3 ply, 5 ply and so one.

3 ply means one Fluted paper between two flat sheets of paper. 5 ply means two fluted paper between 3 flat papers.

This is a 3 ply (2 sheets and one flute)

This is a 3 ply (2 sheets and one flute)

This is a 5 ply (3 sheets and 2 flutes)

This is a 5 ply (3 sheets and 2 flutes)

4. Compression Strength: It means maximum load box can withstand before it starts to bend or deforms.

5. Conditioning: The action of bringing box to state of humidity and temperature in equilibrium with suitable atmosphere. Please note that moisture is the enemy of any paper box.

6. Gloss: It is that property of a substance which causes it to reflect light spectacularly. Usually done by a thin film of plastic or glossy paper to give the box a good look.

I trust I have managed to convey an overview of packaging and its importance, especially in eCommerce logistics business. Comments and queries are welcome.

About the author: Mr. Ritissh Maakhecha is the Managing Director of Kraft Box Containers India Private Limited. The Company are manufacturers of corrugated Boxes and suppliers to various corporates since the past 9 years. Their web presence is www.kraftbox.in . Ritissh can be reached at [email protected].

yes packaging has become a very important part in any eCommerce business, its so important for end consumer to receive their products in a super good condition, But not sure how about large packaging works in eCommerce. Especially in b2b websites like alibaba, wold of chemicals and much more were some times order quantity is so high , how can company can minimize cost

@ Bejoy

Well, to work out on minimizing the cost of your packaging, I need to have complete details of your packaging requirement along with current specifications.

Thanks for your informative article covering many important points from which we have learn many things. hope in future you will write many more articles from you, which will educate and increase our knowledge.

Fibre Foils Ltd.

Manager Purchase.