Running a business is not an easy task; it requires a fine balance of growth development, bottom line administration and resource management. In times of economic growth a lot of it is cut out, however the real challenge comes when the market slows downs.

Improving a business and investing for its growth invariably requires its leaders to focus their attention on a range of aspects that determine the potential and success of the enterprise. From supply, to manufacturing cost, from sales to competitive pricing, from human resources to administration, all these aspects need to be understood, planned and monitored to ensure an optimized business model.

However, investment in management is usually a low priority for SMEs. It is difficult to justify investment on an aspect that does not directly contribute to the bottom line! This article champions the idea that investment in enterprise management is just as crucial for an established SME as it is for a large corporate company. To illustrate this, here are two typical scenarios of Indian SMEs from the manufacturing industry.

Contents

Empowering Manufacturing Businesses

We imagine a potential client enquiring about the cost and delivery delays for a batch of manufactured goods. The first enquiry is with a small manufacturing company that has been in the business for a number of years but has always concentrated on maintaining competitive suppliers and manufacturing processes. They respond to the enquiry by saying that they will place the order for materials with their suppliers, confirm the price of materials and therefore the final cost of manufactured goods, as well as give a delay for delivery based on availability of raw materials from suppliers.

Their response is a probable cost and probable delivery date, with confirmation in a couple of days. In the case of a firm price and delivery date being negotiated, the manufacturer accepts the intrinsic uncertainty of the order and potential risk on either his margin or credibility.

Now let us imagine, that this same enquiry is also sent to an enterprising company that have invested in setting up management system for their stock, material inventory, and manufacturing process flow. The system allows the sales manager to consult their system, whereby realizing that the current manufacturing batch means they will be able to handle this new order next month.

Furthermore, the system indicates that some raw material will be in stock to start this new production while supplies are delivered to complete the order. Archived data of past costs of raw materials indicates a steady increase and the system extrapolates the expected cost. All this information is used to reply to the enquiry with a confirmed price, a delivery date and part delivery of the order before the final delivery date.

As a client, it is clear that the second response to the enquiry is much more serious and professional, most likely resulting in confirmation of the order. A company management system ties up manufacturing process flows and accounting in a way that empowers the management to make learned decisions and increase their prospect for business.

A Progressive and Affordable Solution

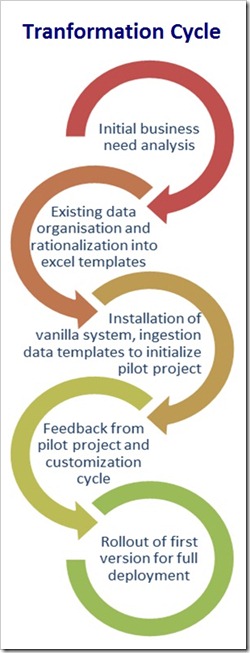

There are many business consultancies that will offer integrated systems for SMEs, offering a range of platforms from a few lakh of Rupees to 6 figure sums. However, such systems are complex to customize, furthermore they require the company employees to adapt to a new work-flow which requires them to use the system and make it effective.

This is a crucial phase of the transformation, for if not enough effort is expanded to expose the employees and tutor them to use the system the whole investment runs the risk of being wasted. So how does a small business start implementing a solution that enables concrete gains on investment while spreading the investment over a larger time in order to minimise the risks.

Managing the inventory of materials

For a manufacturing business, raw materials tracking, stock management, and manufacturing processes are the core of the business and should be tackled first in introducing a management system. This approach has also the advantage of showing the earliest gains for the investment, for it brings an immediate clarity to the management. Here is a 3-point recipe for ensuring a well baked solution:

1. Identify and list all the items manufactured by the business.

This initial step needs a detailed analysis of the variations of the items so as to introduce a unique coding system that will allow identification of these items in the system. For example, a garment manufacturer makes a shirt in different materials and colours. It should have a unique code that is able to represent each variation.

The first part of this code will represent the shirt style, the second part the material used for the shirt (it may come in cotton, in linen, or in synthetic material), and one more part of this code to reflect the material colour or print. This way each variation of the shirt can be uniquely identified in the system. This will also allow for the introduction of bar-codes for each item, allowing for efficient data-entry processes with help of a scanner.

2. Establish the manufacturing processes involved for each item.

This is a crucial step, it will allow the manufacturing process flow to be represented in the system and allow the management to plan production, material supply requirements, manage costing and MRP pricing. This can also shed light on performance related issues.

Taking the example above, a shirt requires a quantity of material, stitching thread, buttons, pattern-making/cutting and stitching labour time. This process will be listed for each items and entered into the system in the form of Bills of Materials (BOMs). This also enables tracking of items cost change as function of raw materials and labour, allowing timely revision of sale prices.

3. Introduce a simple and rapid data capture mechanism for stock and inventory.

This requires the entry into the system of all deliveries from suppliers, all production batches, all stock depletion from sales to clients for the system to be effective. The best way to ensure this is to divide the responsibilities. Sales manager need to be equipped with a computer terminal and use the system to compile delivery challans automatically based on the selection of available stock in the system. This will ensure automated updates of the stock coming out.

Similarly, the production manager, equipped with a bar code scanner can scan production batches into the system once finished. The store materials manager, responsible for accepting deliveries of new supplies should also have a computer terminal to make entries of supply invoices after checking their content.

The investment at this first stage in an enterprise management system should prefer an open-source solution. Any solution requires customisation, even a commercial one. It is therefore better to maximise one’s investment into fine tuning the system than paying licensing fees.

Maintenance and support on mature open-source platforms such as webERP is widely available from a number of IT service companies and is no longer a valid argument in support of commercial platforms. The other requirements are two computer terminals, one for the sales manager and another for the supplies store manager, as well as a hand-held bar-code scanner for the production manager.

This entire exercise can be achieved for less than 3 lakh Rupees including the hardware requirement, and ready to use in a month with dedicated will from the management.

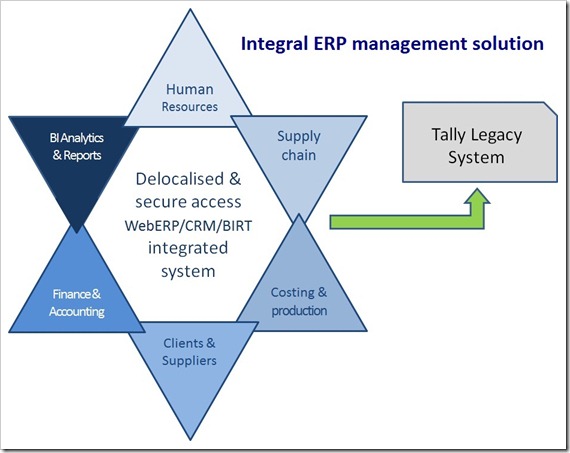

Towards an integral solution

A well established and customized enterprise management system can do much more than this first step. Most SMEs in India use Tally as an accounting platform for the purpose of filing tax returns. A good management system can integrate with Tally, allowing the entire administration process to be carried out on a single platform. Starting with quotations, pro-forma invoicing, payments receipts, deliveries, purchase orders to suppliers, outward payments, salaries and other expenses can all be tracked with a single enterprise management system, which can also be customised to bridge with Tally, thus ensuring tax filing data is promptly updated for the company secretary to compile financial statements.

Even the company human resources, client and supplier management can be integrated (see Techworld.com article). The biggest advantage of slowly integrating the entire business into a single platform is not so much time gain and efficiency, but rather the enormous amount of data collected in a systematic and controlled way, allowing for detailed data analysis and compilation of decision ready dashboards for the top management.

The true value of a well-managed company is the quality of the information available to its business leader, allowing them to concentrate on the business strategy for growth while freeing them from the day to day management of the company. All of this is achievable in a progressive, affordable way but requires a determined will and clarity from the leaders of the company.

[About the Author: Aurovrata is a Frenchman made in India! He heads the Creative strategy and Analytics department of a small consultancy firm offering Business Intelligence and Sustainable Business practices services to SMEs. You can tweet him @aurovrata.]